Tel: 01604 626 266

Franklin Silencers

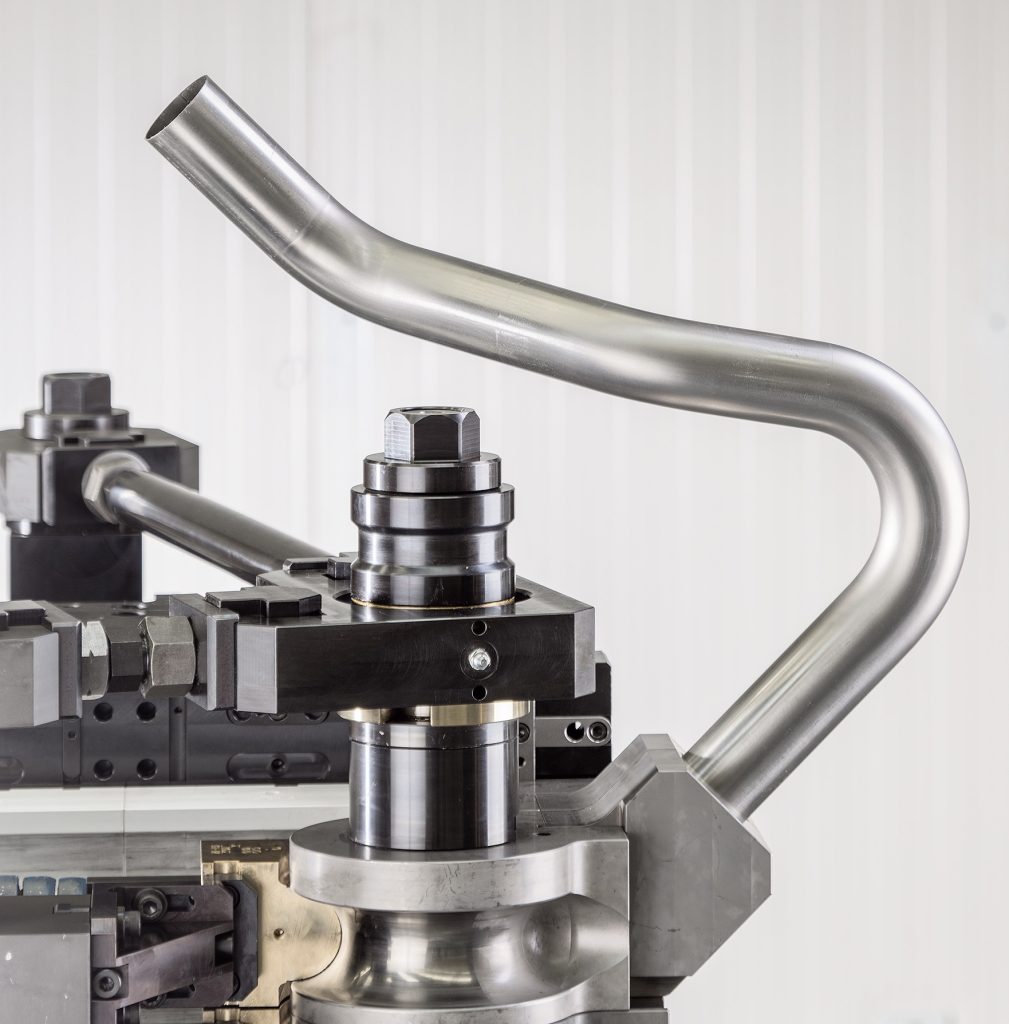

Tube Manipulation

Services

Tube manipulation of a diverse product range

Our tube manipulation services are used to manufacture products across a wide range of industries including exhaust systems, heating/cooling systems and furniture.

Franklin Silencers specialise in thin wall tight radius bending and have a large range of tube manipulation capabilities. We have the ability to manipulate tubular components from 4.6mm diameter up to 127mm diameter in wall thicknesses from 1mm up to 3mm. Alongside tubular components we can also manipulate solid bar up to 25mm in diameter. See our tube bending capability sheet in the downloads section for full details.

We have the capability to manufacture products across a range of material specifications. Mild steel, aluminised steel, and stainless steel. We also have the ability to manufacture specialist products in aluminium and copper.

End forming tooling

Our tube manipulation service is complemented

Our tube manipulation service is complemented by our large range of end forming tooling. Whether this is a simple bead for hose retention, a swage/reduction or more complex fittings we have the ability and expertise to produce complete high-quality products. See our end forming capability sheets in the downloads section for full details.”

Use our tooling capacity sheets

We can utilise our standard tooling to produce your products

When designing products, we recommend using our tooling capacity sheets to ensure we can utilise our standard tooling to produce your products, this ensures products can be manufactured in the most cost-effective way. Our in-house design team can assist you at the early stages of your design process to ensure parts can be manufactured effectively.

All our bending is carried out by our experienced bending operatives using one of our 3 axis CNC bending machines. To ensure all our manipulated products meet our extremely high-quality standards we measure parts using our G-Tube coordinate measuring machine.