Tel: 01604 626 266

Franklin Silencers

Fabrication

Over 50 years in the manufacture of fabricated components

Franklin Silencers have the ability to manufacture an extensive range of fabricated components utilising a wide selection machinery.

We have the ability to laser cut sheet steel and plate up to a thickness of 25mm in a full range of materials. We cut to a high standard both in quality of cut and dimensionally as generally these parts form the basis for most of our fabricated product.

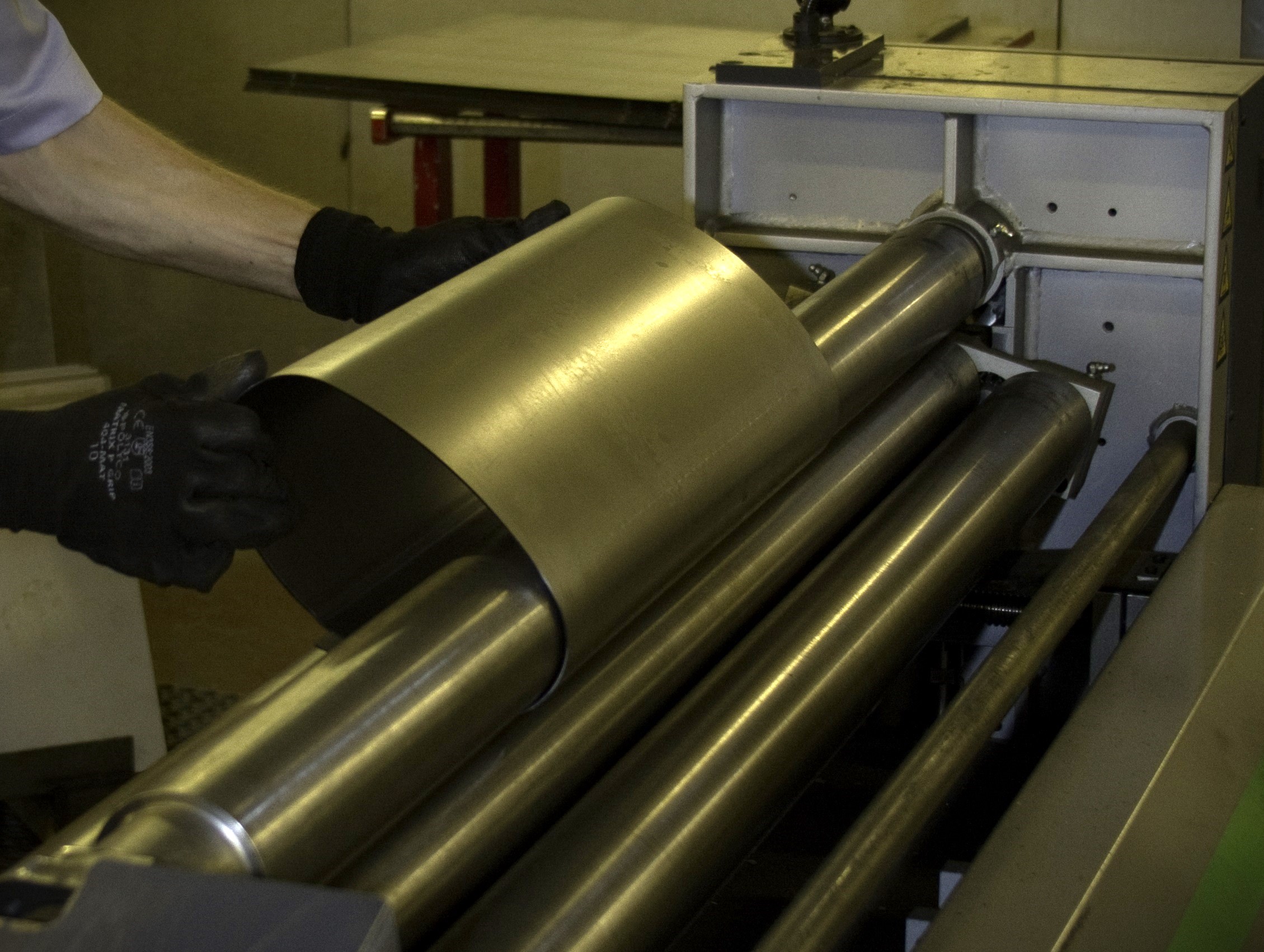

Operating CNC sheet metal rollers allows us to manufacture rolled components from 70mm diameter through to 900mm diameter across a range of thicknesses up to 3mm. These are generally used to form the outer shells for our exhaust silencers however the process can be used to produce a number of products.

Complementary services

Producing high quality complete products

Our full range of complementary services which enable us to produce high quality complete products

All of our fabrication services are complemented by our skilled welding and finishing departments meaning Franklin Silencers can offer you high quality fully finished fabricated assemblies.

Investment in CNC equipment

Continued investment in CNC equipment to ensure we can offer the highest quality service.

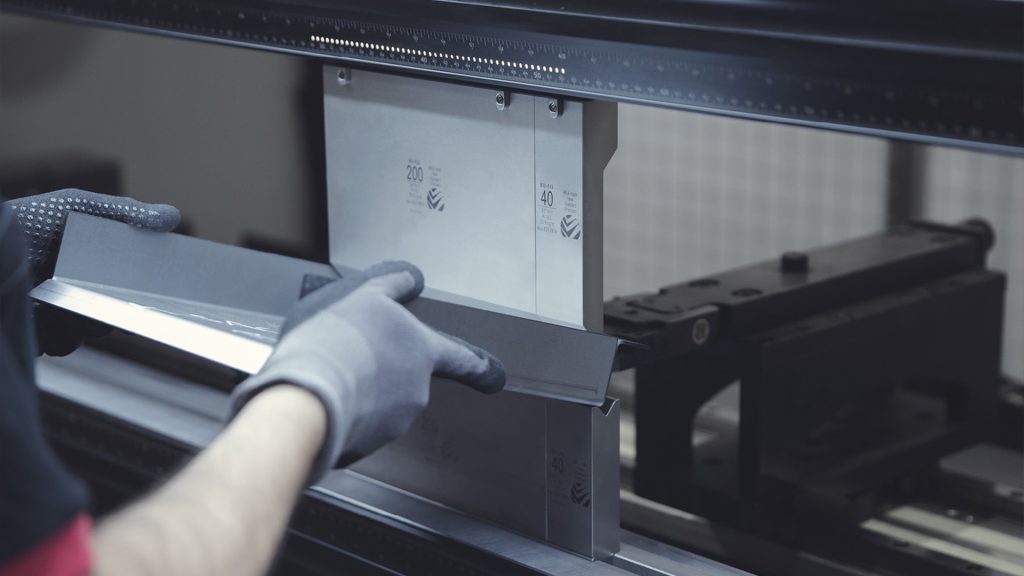

Recent investments have seen us purchase a 2.5 metre CNC press brake which now allows us to fold sheet metal components up to 8mm thick and up to 2.5 metres long. We are continually investing in tooling for this machine to allow us to manufacture a large range of complex parts to extremely high standards.

Below are some images of our Fabrication capability